The design and analysis of aircraft engines is a critical area of focus in the Aerospace and Defense industry, as engines play a key role in reducing fuel consumption, CO2 emissions, and noise levels, while also minimizing maintenance costs.

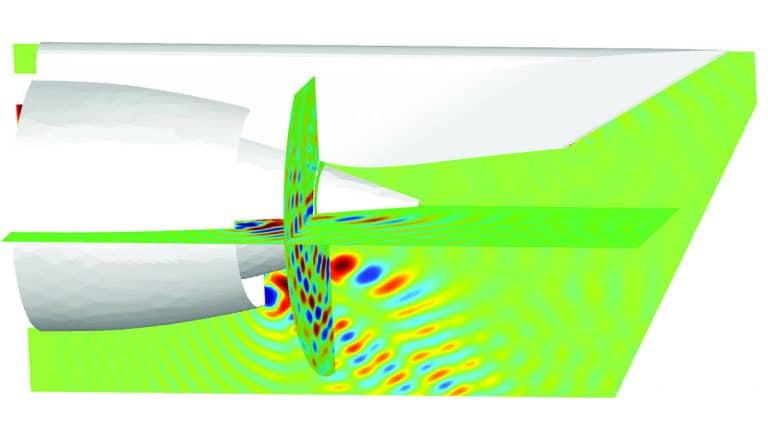

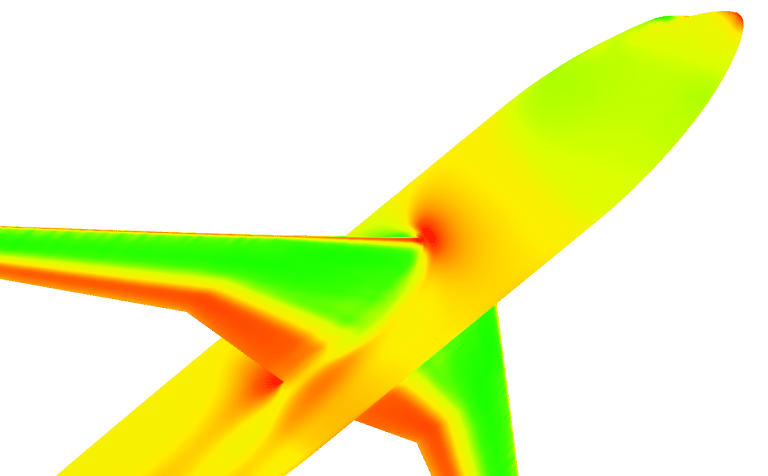

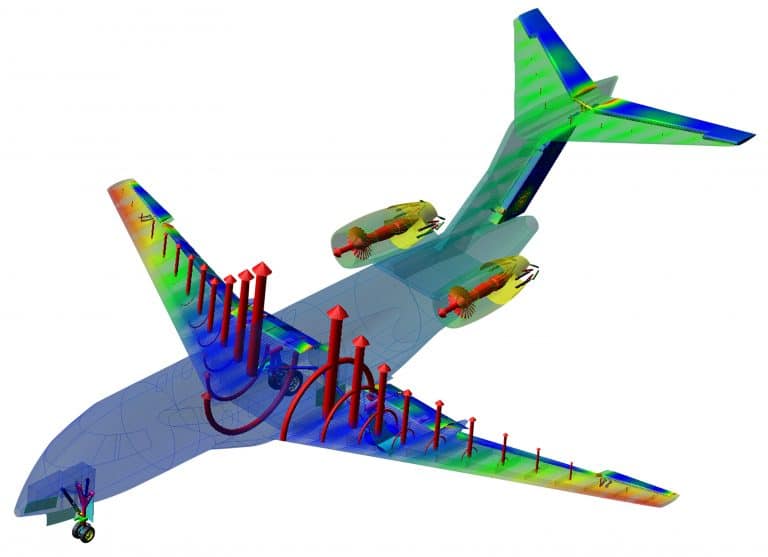

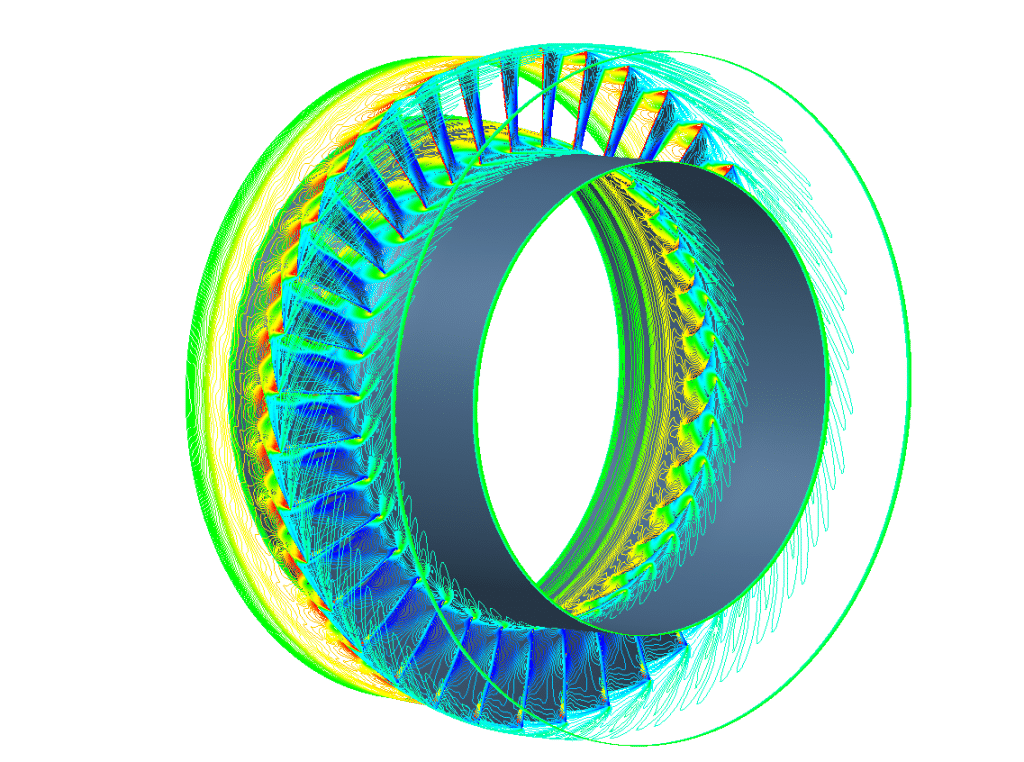

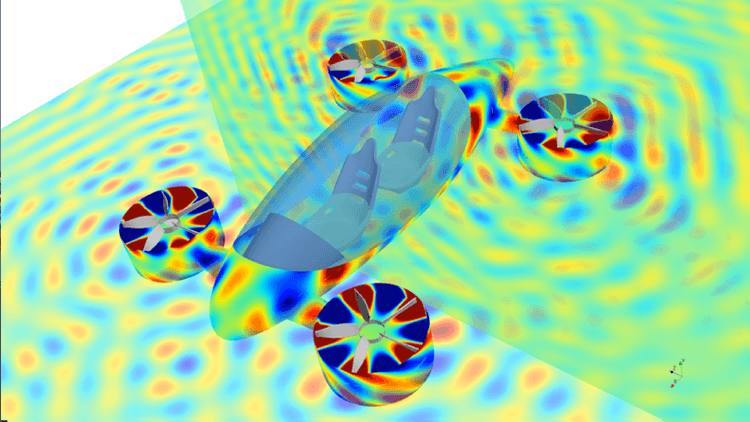

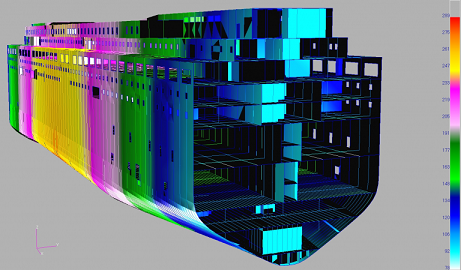

Engine simulations are an essential tool for engineers to optimize the design and performance of aircraft engines. These simulations use a combination of analytical and computational methods to model the behavior of engines under different operating conditions and loads.

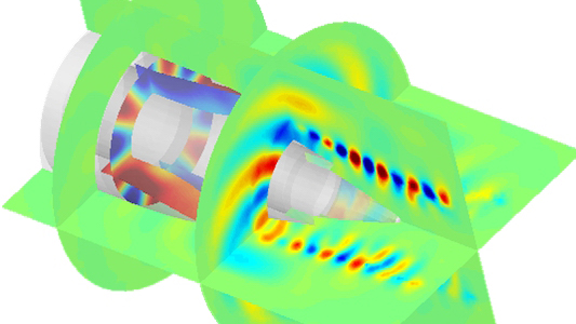

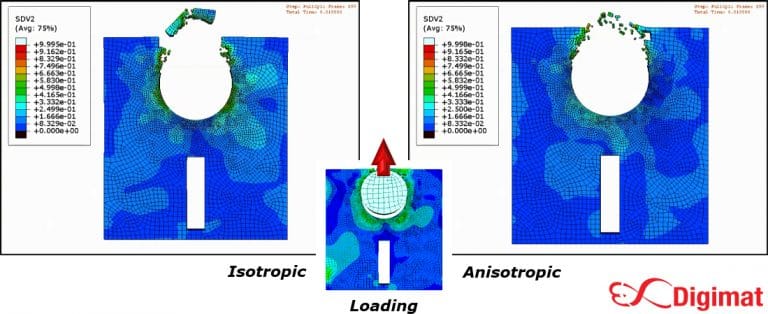

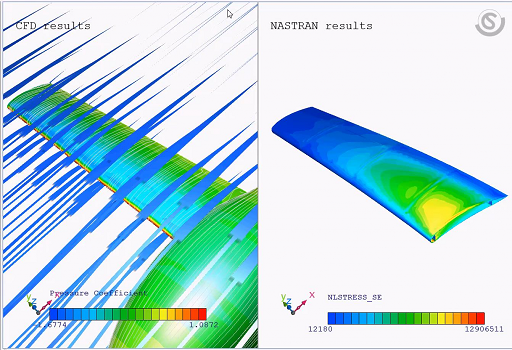

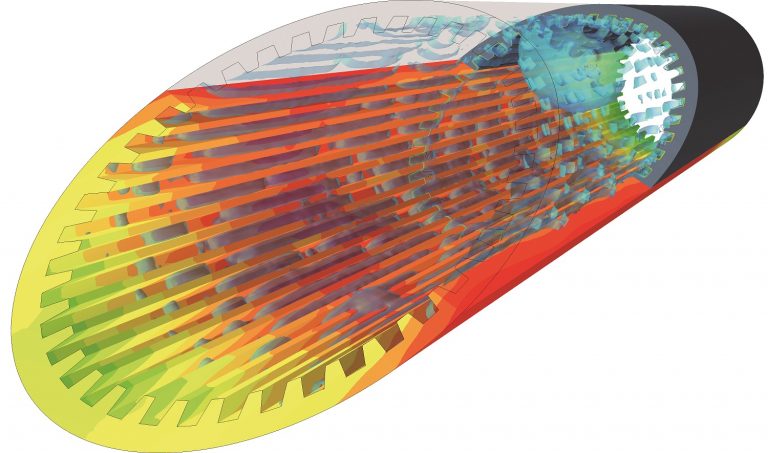

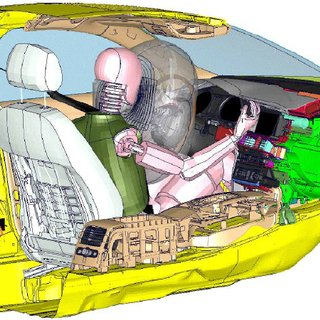

One of the key advantages of engine simulations is the ability to analyze multiple domains and engineering challenges simultaneously. For example, simulations can be used to optimize the design of the engine components, such as the combustion chamber, turbine, and compressor, while also analyzing the heat transfer, fluid dynamics, and structural integrity of the engine.

Engine simulations can also be used to optimize the operation of the engine, such as the fuel injection timing and rate, to improve efficiency and reduce emissions. This can help to meet regulatory constraints on noise and emissions while also reducing operating costs.

Furthermore, engine simulations can be used to analyze the performance of the engine under different operating conditions, such as high altitude or extreme temperatures. This can help to ensure the reliability and safety of the engine in all operating environments.